PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

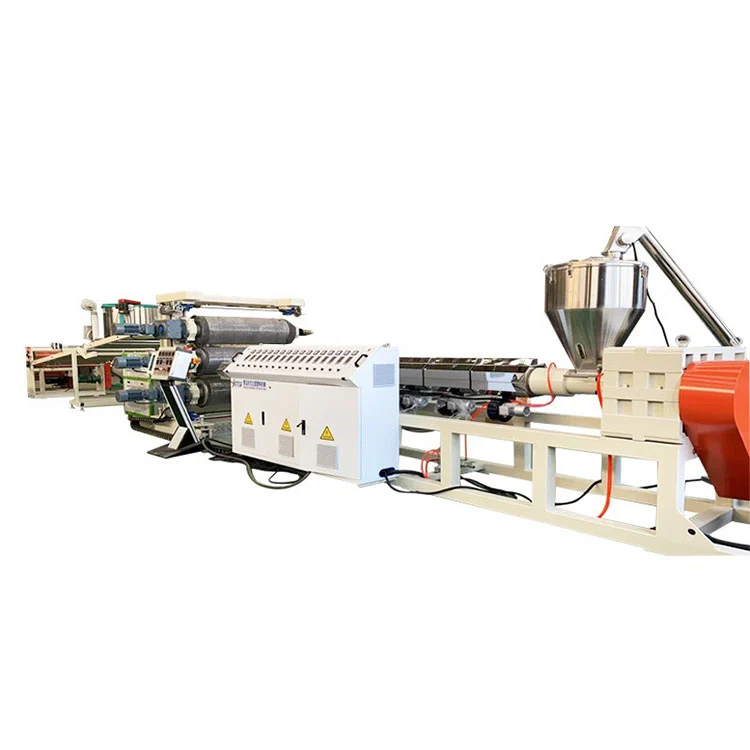

In the competitive landscape of plastic manufacturing, efficiency and innovation are key drivers of success. The PE Chemical Foaming Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a testament to cutting-edge engineering, designed to transform how industries produce lightweight, durable, and versatile PE foam sheets. This machine isn't just another piece of equipment; it's a strategic investment that empowers businesses to meet modern demands for sustainable, cost-effective materials. By leveraging advanced chemical foaming technology, it ensures consistent output with superior surface finish and structural integrity, making it an indispensable tool for packaging, construction, automotive, and consumer goods sectors.

At its core, this extruder excels in producing PE foam sheets with uniform cell structure and excellent thermal insulation properties. The process involves precise control of chemical blowing agents, resulting in sheets that are not only lightweight but also robust enough for demanding applications. Imagine reducing material usage by up to 30% while maintaining strength—this machine makes it possible. Its automated systems minimize human error, ensuring every batch meets high-quality standards. Whether you're creating protective packaging for fragile items or insulation panels for buildings, the PE Chemical Foaming Sheet Extruder Machine delivers reliability and performance that boost productivity and profitability.

The PE Chemical Foaming Sheet Extruder Machine is packed with features that address common industry challenges. For instance, its energy-efficient design reduces power consumption by up to 20% compared to conventional models, thanks to optimized heating and cooling mechanisms. The use of high-grade corrosion-resistant materials extends the machine's lifespan, minimizing downtime and maintenance costs. Additionally, the intuitive touchscreen interface allows operators to monitor and adjust parameters in real-time, fostering a seamless workflow. This level of precision ensures that users can achieve consistent foam density and thickness, which is critical for applications like automotive interiors or food packaging where uniformity is paramount.

Another standout benefit is the machine's versatility. It accommodates various PE grades and additives, enabling customization for specific needs. From producing anti-static sheets for electronics to water-resistant variants for outdoor use, the possibilities are vast. Qingdao Eaststar Plastic Machinery Co., Ltd. has integrated smart sensors that detect anomalies early, preventing costly defects. This proactive approach not only saves resources but also builds trust with clients who rely on consistent quality. By choosing this extruder, businesses aren't just buying a machine—they're investing in a partnership that prioritizes innovation and long-term value.

Who benefits from the PE Chemical Foaming Sheet Extruder Machine? Think of manufacturers in the packaging industry struggling with rising material costs and environmental regulations. This machine offers a solution by producing lightweight, recyclable foam sheets that cut shipping expenses and reduce carbon footprints. In construction, contractors use these sheets for insulation, benefiting from their easy installation and durability. Even in the automotive sector, where weight reduction is crucial for fuel efficiency, this extruder provides materials for door panels and dashboards. Small workshops and large factories alike find it adaptable, thanks to its modular design that scales with production needs.

Users often report a sense of relief and empowerment after integrating this machine into their operations. No more dealing with inconsistent foam quality or frequent breakdowns. Instead, they experience smoother production cycles, faster turnaround times, and happier customers. For example, a packaging company might see a 15% increase in order fulfillment speed, while a builder appreciates the reduced waste during installation. This emotional boost translates into tangible business growth, as reliable equipment fosters confidence and allows teams to focus on innovation rather than troubleshooting.

Many businesses face the challenge of balancing cost and performance in foam sheet production. The PE Chemical Foaming Sheet Extruder Machine addresses this with data-driven precision. Below is a table outlining core parameters that highlight its capabilities:

| Parameter | Specification |

|---|---|

| Output Capacity | 200-500 kg/h, adjustable based on material and thickness |

| Sheet Width Range | 600-2000 mm, customizable for various applications |

| Foam Density | 0.03-0.3 g/cm³, ensuring lightweight yet strong sheets |

| Power Consumption | Approx. 80-120 kW, optimized for energy savings |

| Operating Temperature | 150-250°C, with precise thermal control for consistency |

| Machine Dimensions | Length: 10-15 m, Width: 3-5 m, Height: 2-3 m (modular setups available) |

These specs demonstrate how the machine tackles issues like high operational costs and variable product quality. For instance, the adjustable output allows small batches for niche markets or large runs for mass production, reducing material waste. The controlled foam density means users can achieve specific insulation or cushioning properties without guesswork. By providing such transparency, Qingdao Eaststar Plastic Machinery Co., Ltd. ensures that clients can make informed decisions, aligning the machine's features with their unique requirements.

In a crowded market, the PE Chemical Foaming Sheet Extruder Machine distinguishes itself through innovation and reliability. Unlike older models that rely on mechanical foaming, this unit uses advanced chemical agents for finer cell structure, resulting in sheets with better compression resistance and surface smoothness. Competitors often lack the integrated cooling systems that Eaststar includes, which prevent overheating and extend component life. Moreover, the machine's modular design allows for easy upgrades, so it evolves with technological advancements. This future-proof approach means buyers aren't stuck with obsolete equipment—a common pain point in the industry.

Customer support is another differentiator. Qingdao Eaststar Plastic Machinery Co., Ltd. offers comprehensive training and after-sales services, including remote diagnostics and spare parts availability. This reduces downtime and builds long-term relationships. Users appreciate the peace of mind that comes with knowing expert help is just a call away, whether they're in Asia, Europe, or the Americas. Such global accessibility, combined with the machine's robust performance, makes it a preferred choice for businesses aiming to stay ahead of trends.

What materials can the PE Chemical Foaming Sheet Extruder Machine process?

It primarily handles polyethylene (PE) resins, including LDPE, HDPE, and LLDPE, with compatibility for additives like flame retardants or colorants. This flexibility allows for tailored solutions across industries.

How does the chemical foaming process improve sheet quality?

Chemical foaming uses controlled agents to create uniform bubbles within the material, enhancing insulation, reducing weight, and improving surface finish compared to physical foaming methods. This results in sheets that are easier to handle and more consistent in performance.

Is the machine difficult to operate for beginners?

Not at all. The user-friendly interface includes automated settings and step-by-step guides, making it accessible for new operators. Training sessions provided by Qingdao Eaststar Plastic Machinery Co., Ltd. ensure quick proficiency.

What maintenance is required to keep the extruder running smoothly?

Routine checks involve cleaning the screw and barrel, inspecting electrical components, and lubricating moving parts. The machine's design minimizes maintenance frequency, with most tasks taking less than an hour.

Can the extruder be customized for specific production needs?

Yes, modular options allow adjustments in output speed, sheet dimensions, and foam density. Custom configurations are available to match unique client requirements, ensuring optimal integration into existing lines.

How does this machine support sustainability goals?

By reducing material waste and energy consumption, it helps lower carbon emissions. The PE foam sheets produced are often recyclable, aligning with eco-friendly initiatives in packaging and construction.

What is the typical lead time for delivery and installation?

Delivery usually takes 4-6 weeks after order confirmation, with installation completed within a week by certified technicians. Expedited options are available for urgent projects.

Ultimately, the PE Chemical Foaming Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. represents more than just advanced technology—it's a catalyst for growth and efficiency. By addressing real-world challenges with data-backed solutions, it empowers users to innovate and expand their market presence. Whether you're upgrading an existing line or starting anew, this machine offers the reliability and flexibility needed to thrive in today's dynamic industries.