PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

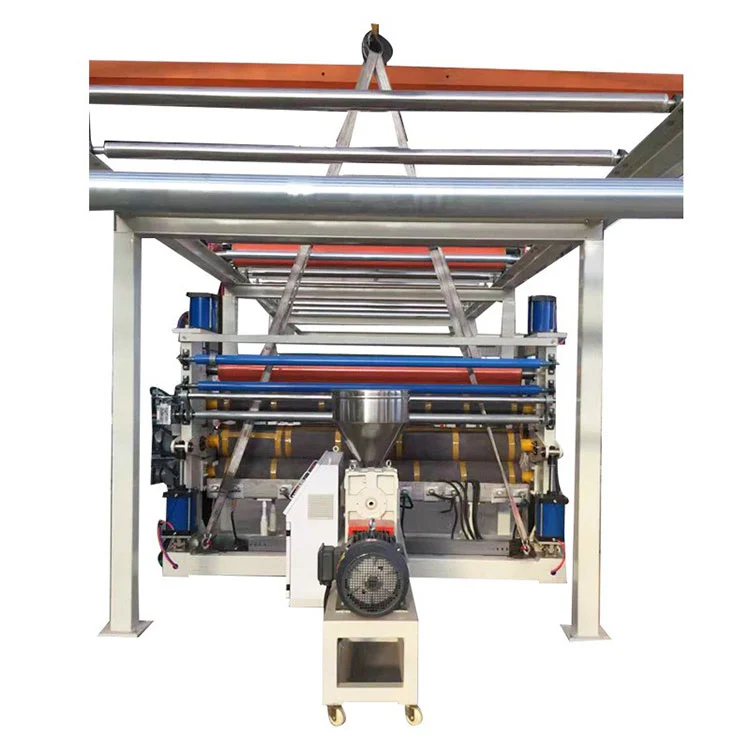

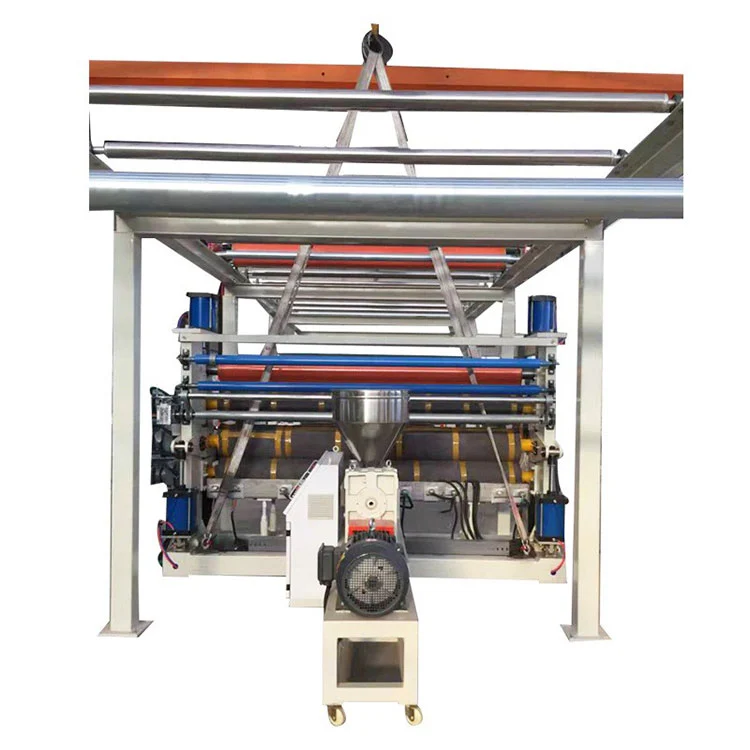

Step into the world of premium automotive manufacturing with the TPE Car Mat Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. Designed for excellence, this machine transforms the production of durable, eco-friendly car mats, combining innovation with practical functionality. It is the go-to solution for businesses aiming to elevate their product quality while optimizing operational efficiency. Whether you are a seasoned manufacturer or expanding your production line, this machine offers reliability and precision that set new industry standards. Let’s explore how this cutting-edge equipment can reshape your manufacturing process and deliver outstanding results.

The TPE Car Mat Sheet Extruder Machine is engineered to handle thermoplastic elastomers (TPE) with exceptional ease, producing high-quality sheets ideal for automotive floor mats. Its versatility extends to various applications, including custom-designed mats for different vehicle models. With intelligent control systems, the machine ensures consistent thickness, texture, and durability, meeting the rigorous demands of modern automotive interiors. By integrating advanced heating and cooling mechanisms, it minimizes material waste and maximizes output, making it a valuable asset for any production facility.

What makes the TPE Car Mat Sheet Extruder Machine stand out? First, its robust construction guarantees long-term reliability, reducing downtime and maintenance costs. The use of high-grade components ensures smooth operation even under heavy usage. Secondly, the machine incorporates energy-efficient technologies, lowering operational expenses while supporting sustainable manufacturing practices. Additionally, its user-friendly interface allows operators to adjust settings seamlessly, ensuring precision in every batch. From superior material compatibility to enhanced safety features, every aspect is designed to deliver unparalleled performance.

Many manufacturers face issues like inconsistent sheet quality, high energy consumption, and frequent machine breakdowns. The TPE Car Mat Sheet Extruder Machine addresses these pain points head-on with innovative solutions. For instance, its precision extrusion system eliminates variations in thickness, while the integrated cooling unit accelerates production cycles. Below is a detailed parameter table highlighting how specific features tackle common problems:

| Challenge | Solution | Technical Parameters |

|---|---|---|

| Inconsistent sheet thickness | Advanced screw design and temperature control | Thickness tolerance: ±0.1mm; Output: 150-300 kg/h |

| High energy usage | Energy-saving motor and optimized heating | Power consumption: 25-40 kW; Heating efficiency: 95% |

| Frequent maintenance needs | Durable components and self-diagnostic system | Maintenance interval: 500 hours; Lifespan: 10+ years |

This machine is perfect for automotive parts manufacturers, custom mat producers, and recycling facilities looking to incorporate TPE materials. It thrives in environments where high-volume, consistent output is essential, such as assembly lines for original equipment manufacturers (OEMs) or aftermarket suppliers. Additionally, businesses focused on sustainability will appreciate its ability to process recycled TPE, reducing environmental impact. From small workshops to large industrial plants, the extruder adapts to diverse operational scales, ensuring flexibility and scalability.

Imagine a production floor where delays are rare, quality is consistently high, and operational costs are under control. Users of the TPE Car Mat Sheet Extruder Machine report a significant boost in productivity and a reduction in material waste. The machine’s reliability translates into peace of mind, allowing teams to focus on innovation rather than troubleshooting. For business owners, this means faster ROI and enhanced competitiveness in the market. The emotional reward of delivering superior products that meet customer expectations cannot be overstated—it builds trust and fosters long-term loyalty.

Unlike conventional extruders, this model from Qingdao Eaststar Plastic Machinery Co., Ltd. features a modular design that allows for easy upgrades and customization. Its compatibility with a wide range of TPE compounds—including recycled materials—sets it apart from competitors. Moreover, the machine’s intelligent monitoring system provides real-time data analytics, enabling proactive maintenance and optimizing production schedules. These差异化亮点 ensure that it not only meets but exceeds industry standards, offering a future-proof solution for evolving market needs.

What types of TPE materials can the machine process?

The extruder is compatible with various TPE grades, including virgin and recycled compounds. It handles materials with different melt flow indexes, ensuring flexibility for diverse production requirements.

How does the machine ensure consistent sheet quality?

Through precision temperature control, advanced screw geometry, and real-time monitoring, the machine maintains uniform thickness and texture, minimizing defects and enhancing product reliability.

What is the typical maintenance schedule?

Routine maintenance is recommended every 500 hours of operation, focusing on cleaning, lubrication, and component checks. The self-diagnostic system alerts operators to potential issues, reducing unplanned downtime.

Can the machine be integrated into existing production lines?

Yes, it features standardized interfaces and modular components that facilitate seamless integration with auxiliary equipment like cutters, rollers, and packaging systems.

What safety features are included?

The machine comes with emergency stop buttons, overload protection, and insulated heating zones to ensure operator safety and prevent accidents during operation.

How energy-efficient is the extruder compared to older models?

It incorporates high-efficiency motors and optimized heating elements, reducing power consumption by up to 20% compared to traditional extruders, which lowers operational costs and environmental impact.

Is training provided for operators?

Qingdao Eaststar Plastic Machinery Co., Ltd. offers comprehensive training sessions, including hands-on operation and troubleshooting, to ensure users maximize the machine’s potential.

What is the warranty period?

The standard warranty covers 12 months from the date of purchase, with options to extend coverage for critical components based on customer needs.