PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

Imagine a machine that transforms raw polyamide granules into high-performance sheets with precision, consistency, and remarkable efficiency. Welcome to the world of the PA Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This state-of-the-art equipment is engineered to produce superior-quality PA (polyamide) sheets, which are widely used across industries for their exceptional strength, thermal stability, and resistance to wear and chemicals. From automotive components and electrical insulators to food packaging and consumer goods, this extruder opens up a world of manufacturing possibilities.

At the heart of this machine lies cutting-edge extrusion technology, meticulously designed to handle the unique properties of polyamide materials. Unlike conventional extruders, our PA Sheet Extruder ensures uniform melting, precise thickness control, and minimal material waste. The result? Flawless sheets that meet stringent industry standards, boost your production output, and reduce operational costs. Whether you're a large-scale manufacturer or a growing enterprise, this machine adapts to your needs, delivering reliability day in and day out.

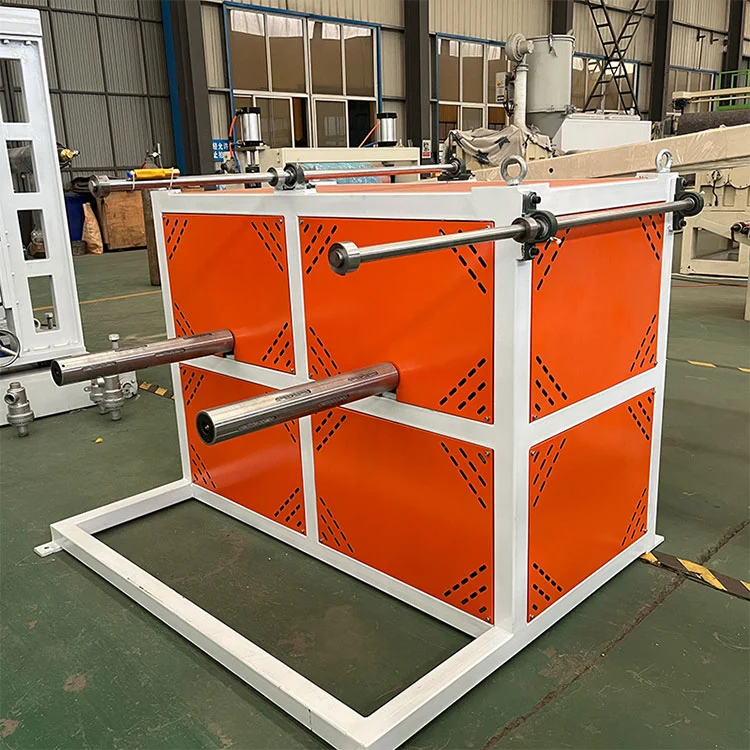

What makes the PA Sheet Extruder Machine a standout choice? Let's dive into its core strengths. First, the robust construction using high-grade stainless steel and corrosion-resistant components guarantees longevity, even in demanding environments. The advanced screw and barrel design optimizes material flow, preventing degradation and ensuring consistent sheet quality. Additionally, the user-friendly control system—featuring an intuitive touchscreen interface—allows operators to monitor and adjust parameters with ease, minimizing downtime and human error.

But it doesn't stop there. Our extruder incorporates energy-efficient drives and heating elements, cutting power consumption by up to 20% compared to older models. This not only lowers your carbon footprint but also trims utility bills, making it a smart investment for eco-conscious businesses. Plus, with optional customization for sheet width, thickness, and output speed, you can tailor the machine to your specific production requirements. At Qingdao Eaststar, we back every unit with comprehensive technical support and a warranty, so you can focus on growing your business with peace of mind.

Many manufacturers struggle with inconsistent sheet thickness, leading to product rejections and wasted materials. Our PA Sheet Extruder tackles this head-on with precision calibration and real-time monitoring. For instance, in automotive applications, where tight tolerances are critical, the machine delivers sheets with deviations of less than ±0.1mm. Below, we outline common pain points and how our extruder addresses them, supported by key technical parameters.

Challenge: Inefficient melting causing material waste and weak sheets.

Solution: Multi-zone temperature control and optimized screw design for homogeneous melting.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Output Capacity | 200-800 kg/h (adjustable) |

| Sheet Width Range | 500-2000 mm |

| Thickness Tolerance | ±0.1 mm |

| Power Consumption | 15-30% lower than industry average |

Challenge: High maintenance costs and frequent breakdowns.

Solution: Durable components and easy-access design for simplified servicing.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Maintenance Intervals | Up to 6 months under normal use |

| Noise Level | < 75 dB |

| Cooling System | Efficient water circulation for stable operation |

The PA Sheet Extruder Machine is ideal for a diverse range of users. Industrial manufacturers in sectors like automotive, packaging, and electronics rely on it to produce durable parts such as gears, insulating layers, and protective casings. Small to medium enterprises appreciate its scalability and low operational costs, enabling them to compete with larger players. Even research and development labs use it for prototyping new materials, thanks to its precision and flexibility. In practical terms, envision a factory floor where sheets are continuously produced for injection molding or a packaging line where strong, heat-resistant films are essential—this machine fits seamlessly into such scenarios.

Beyond industrial settings, businesses focused on sustainability find value in the extruder's ability to recycle polyamide waste into usable sheets, supporting circular economy initiatives. By integrating this equipment, companies not only enhance their production capabilities but also contribute to environmental conservation. The sense of achievement? Unmatched. Users report feeling empowered, knowing they can deliver top-notch products consistently, build customer trust, and expand their market reach without the headaches of machine failures or quality issues.

Picture the relief of eliminating production bottlenecks and the pride in showcasing flawlessly manufactured goods. With the PA Sheet Extruder, those moments become everyday realities. It solves core problems like material inconsistency, which often leads to client complaints and financial losses. For a factory manager, this means fewer sleepless nights worrying about deadlines; for a business owner, it translates into higher profitability and a stronger brand reputation. The machine doesn't just extrude sheets—it builds confidence and fuels growth.

Consider a testimonial from a satisfied user: "Since switching to Qingdao Eaststar's extruder, our rejection rates dropped by 40%, and team morale soared. We're now taking on bigger projects with ease." This emotional connection stems from reliability—the assurance that the machine will perform under pressure, adapt to changing demands, and support long-term success.

In a crowded market, the PA Sheet Extruder Machine stands out through innovation and customer-centric design. While competitors may offer basic extrusion, we integrate smart features like IoT connectivity for remote monitoring and predictive maintenance. Our focus on energy efficiency and customization options—such as tailored screw configurations for different PA grades—ensures you get a solution, not just a product. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. brings decades of expertise, with a global network of service centers for prompt assistance. This commitment to excellence means you invest in a partner, not just a machine.

Another key differentiator is the attention to detail in safety and ergonomics. Features like emergency stop buttons, enclosed moving parts, and clear labeling reduce accident risks, fostering a safer workplace. Combined with competitive pricing and flexible financing, these aspects make our extruder an unbeatable value proposition.

What types of polyamide materials can the extruder process?

The machine handles various PA grades, including PA6, PA66, and reinforced blends with fillers like glass fiber. It's compatible with both virgin and recycled materials, offering versatility for different applications.

How long does installation and training take?

Typically, installation is completed within 2-3 days, followed by a 1-2 day training session for your operators. We provide detailed manuals and ongoing support to ensure smooth integration.

Can the extruder be customized for specific output requirements?

Absolutely. We offer modifications in screw diameter, die width, and control systems to match your desired output rates and sheet dimensions. Discuss your needs with our engineering team for a tailored solution.

What maintenance is required, and how often?

Routine checks include cleaning the screw and barrel, inspecting heaters, and lubricating moving parts. Under normal use, plan for minor maintenance every 3-6 months, with comprehensive servicing annually. Our design minimizes downtime during these activities.

Is technical support available after purchase?

Yes, Qingdao Eaststar provides 24/7 remote assistance, on-site service visits, and spare parts supply. Our goal is to keep your operations running smoothly with minimal interruptions.

How energy-efficient is this machine compared to others?

Through optimized heating and drive systems, our extruder consumes 15-30% less energy than conventional models. This efficiency translates to lower operating costs and a reduced environmental impact over time.

From its robust build to its intelligent features, the PA Sheet Extruder Machine embodies Qingdao Eaststar's dedication to quality and innovation. It's more than equipment—it's a catalyst for progress, designed to help you achieve manufacturing excellence with confidence and ease.