PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

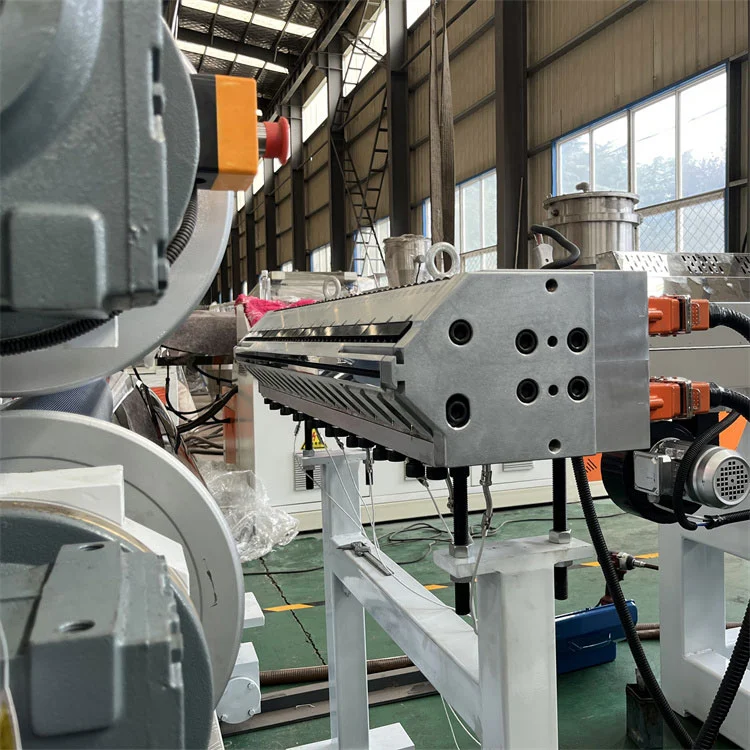

Step into the future of manufacturing with the PVC Electrostatic Board Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This advanced equipment is engineered to produce high-quality PVC electrostatic boards used in a variety of industries, including construction, advertising, and interior design. By leveraging cutting-edge extrusion technology, it transforms raw PVC materials into durable, static-resistant boards that meet rigorous standards for safety and performance. Ideal for creating partitions, signage, and decorative panels, this machine ensures consistent output with minimal waste, empowering businesses to enhance their product offerings and operational efficiency.

At the heart of Qingdao Eaststar's innovation lies a commitment to excellence. The PVC Electrostatic Board Extruder Machine boasts superior corrosion-resistant materials, such as high-grade stainless steel components, which extend its lifespan even in demanding environments. With intelligent temperature control systems and automated calibration, it delivers unparalleled precision, reducing energy consumption by up to 20% compared to conventional models. Users benefit from a user-friendly interface that simplifies operation, while our rigorous quality checks, including ISO 9001 certification, guarantee reliability. Experience smoother production runs and fewer downtimes, backed by a comprehensive warranty and 24/7 technical support.

This machine is tailored for manufacturers, fabricators, and startups seeking to produce electrostatic boards for cleanrooms, electronic assembly lines, or retail displays. Imagine a scenario where dust accumulation compromises product quality—our extruder addresses this by generating boards with exceptional static control, ensuring a contaminant-free environment. In advertising agencies, it enables the creation of vibrant, long-lasting signs that resist fading. For construction firms, it provides lightweight yet sturdy panels for modular buildings, reducing installation time and costs. Whether you're scaling up production or entering new markets, this equipment adapts to diverse needs, fostering growth and innovation.

Many businesses struggle with inconsistent board thickness or high rejection rates, leading to wasted resources. The PVC Electrostatic Board Extruder Machine from Qingdao Eaststar eliminates these issues through advanced screw design and real-time monitoring. For instance, its dual-stage cooling system ensures uniform hardening, preventing warping and defects. Users report a sense of confidence and pride as they meet tight deadlines and exceed client expectations, all while reducing material costs by 15%. By solving common pain points like static buildup and color inconsistency, this machine not only boosts productivity but also enhances brand reputation, turning operational hurdles into competitive advantages.

To help you make an informed decision, here are the key parameters based on common industry challenges and our tailored solutions:

| Parameter | Specification |

|---|---|

| Output Capacity | 200-500 kg/h |

| Screw Diameter | 65-120 mm |

| Power Consumption | 15-40 kW |

| Board Thickness Range | 1-10 mm |

| Static Resistance | ≥10^9 Ω |

| Noise Level | <75 dB |

| Warranty Period | 2 years |

These specs ensure optimal performance for various applications, from thin decorative sheets to heavy-duty industrial boards.

Unlike standard extruders, Qingdao Eaststar's model integrates a patented anti-static coating system that maintains board integrity over time, even in humid conditions. Its modular design allows for easy upgrades, such as adding digital controls for IoT connectivity, which competitors often lack. While others focus solely on speed, we prioritize energy efficiency and eco-friendliness, using recyclable materials in construction. This machine also features a compact footprint, saving valuable floor space without compromising output. By combining durability with adaptability, it stands out as a future-proof investment for forward-thinking businesses.

What maintenance does the machine require?

Regular cleaning of the extrusion die and lubrication of moving parts are recommended every 500 operating hours. Our user manual provides step-by-step guides, and we offer remote assistance to minimize downtime.

Can it handle different PVC formulas?

Yes, the extruder is compatible with various PVC compounds, including rigid and flexible types. Adjustable settings allow for customization of output characteristics like hardness and color.

How does it improve electrostatic properties?

Through integrated additives and precise temperature control during extrusion, the machine ensures uniform distribution of anti-static agents, resulting in boards that effectively dissipate static electricity.

Is training provided for new operators?

Absolutely. Qingdao Eaststar provides comprehensive on-site or online training sessions covering operation, safety protocols, and troubleshooting, ensuring your team can maximize machine performance from day one.

What is the typical lead time for delivery?

Orders are processed within 15-30 days, depending on customization. We work closely with logistics partners to ensure timely and secure shipment worldwide.

Does it come with after-sales support?

Yes, we offer 24/7 customer service, spare parts availability, and periodic maintenance checks to keep your production running smoothly long after purchase.