PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

Welcome to the future of plastic sheet manufacturing with the PVDF Sheet Extruder Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. This advanced equipment is meticulously engineered for producing high-quality polyvinylidene fluoride (PVDF) sheets, which are widely used in industries requiring exceptional chemical resistance, thermal stability, and durability. From architectural cladding and chemical processing equipment to electrical insulation and medical devices, this machine empowers businesses to create sheets that meet stringent international standards, ensuring reliability in demanding environments. With robust construction and cutting-edge technology, it transforms raw PVDF material into precise, uniform sheets that elevate product performance and expand market opportunities.

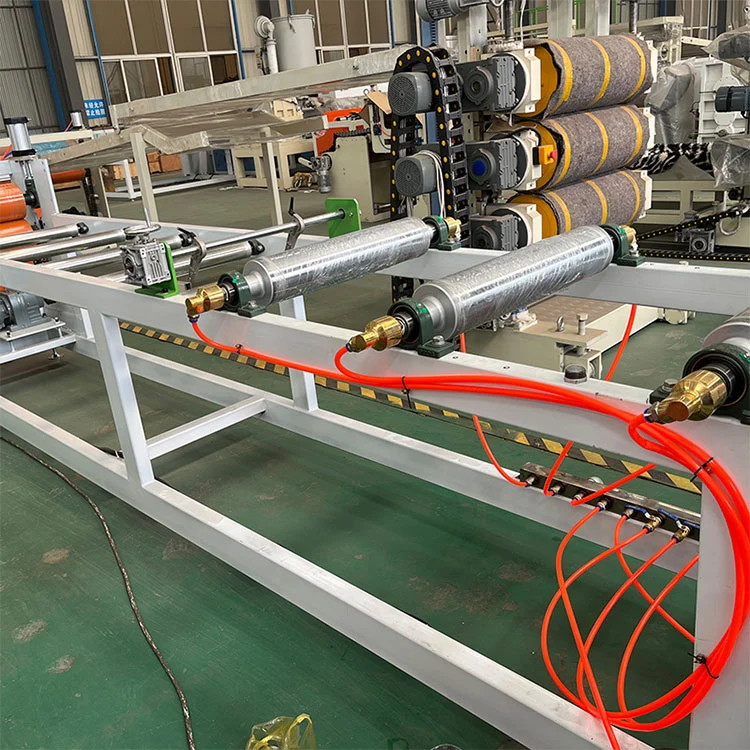

At the heart of this extruder lies a fusion of innovation and precision. The machine features a high-efficiency screw design that ensures optimal melting and homogenization of PVDF resin, reducing energy consumption by up to 20% compared to conventional models. Its modular construction allows for easy customization, catering to specific thickness and width requirements without compromising on speed. The integrated digital control system provides real-time monitoring of temperature, pressure, and output rates, enabling operators to maintain consistency and minimize waste. Additionally, the use of corrosion-resistant materials in key components extends the machine's lifespan, making it a sustainable investment for long-term production goals.

Imagine facing the challenge of inconsistent sheet thickness that leads to product rejections and wasted resources. With the PVDF Sheet Extruder Machine, Qingdao Eaststar addresses this by incorporating a precision die system and automated calibration, ensuring every sheet meets exact specifications. Below is a summary of key parameters that highlight its capabilities:

| Parameter | Specification |

|---|---|

| Output Capacity | 100-500 kg/h |

| Sheet Thickness Range | 0.5 mm to 10 mm |

| Sheet Width | Up to 2000 mm |

| Power Consumption | Energy-efficient, with savings up to 25% |

| Control System | Fully automated PLC with touchscreen interface |

This machine is ideal for manufacturers in sectors like construction, automotive, and chemical engineering, where precision and reliability are non-negotiable. Whether used in factory settings for mass production or in R&D labs for prototyping, it adapts seamlessly to diverse workflows. Users often report a sense of confidence and empowerment, as the machine eliminates common issues like material degradation and uneven surfaces, allowing them to focus on innovation rather than troubleshooting. By streamlining operations, it not only boosts productivity but also enhances the overall quality of end-products, fostering trust and satisfaction among clients.

What sets this extruder apart from competitors is its holistic approach to user needs. Unlike standard machines that may require frequent maintenance, Qingdao Eaststar's model includes self-diagnostic features and remote support capabilities, reducing downtime significantly. The cooling system is optimized for rapid heat dissipation, ensuring consistent sheet quality even during extended runs. Furthermore, the company's commitment to after-sales service means that users receive comprehensive training and spare parts availability, creating a partnership rather than just a transaction. This dedication to excellence is reflected in the machine's ability to handle various PVDF grades, from standard to high-purity formulations, without additional modifications.

Frequently asked questions provide further insight into the machine's reliability and ease of use. Here are some common queries answered in detail:

What is the typical setup time for the PVDF Sheet Extruder Machine?

The machine is designed for quick installation, usually taking 2-3 days with guided support from our technicians. Pre-assembled modules and clear documentation streamline the process, minimizing disruption to your operations.

How does it handle different PVDF material grades?

Equipped with adjustable screw configurations and temperature zones, the extruder accommodates a wide range of PVDF resins, including those with additives for UV resistance or flame retardancy, ensuring versatile application across industries.

Is training provided for operators?

Yes, Qingdao Eaststar offers onsite or virtual training sessions covering operation, maintenance, and troubleshooting, empowering your team to maximize machine efficiency and lifespan.

What maintenance routines are recommended?

Routine checks every 500 operating hours include cleaning the die head, inspecting drives, and lubricating moving parts. The automated alerts in the control system help schedule maintenance proactively, preventing unexpected breakdowns.

Can the machine be integrated with existing production lines?

Absolutely, it features standardized interfaces and compatibility with common auxiliary equipment, allowing seamless integration to enhance your current setup without major overhauls.

Beyond technical prowess, this machine embodies a commitment to sustainability. By optimizing material usage and reducing energy waste, it supports eco-friendly manufacturing practices. Clients in regions with strict environmental regulations appreciate how it aligns with green initiatives, while its durability means fewer replacements and less resource consumption over time. The emotional payoff is palpable—users feel a renewed sense of pride in delivering products that not only perform exceptionally but also contribute to a healthier planet. This aligns perfectly with the vision of Qingdao Eaststar Plastic Machinery Co., Ltd., where innovation meets responsibility.

In summary, the PVDF Sheet Extruder Machine stands as a testament to engineering excellence, tailored for those who demand precision, efficiency, and long-term value. From its user-friendly controls to its robust build, every aspect is crafted to inspire confidence and drive success. Explore how this machine can transform your production capabilities and open new avenues for growth.