PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

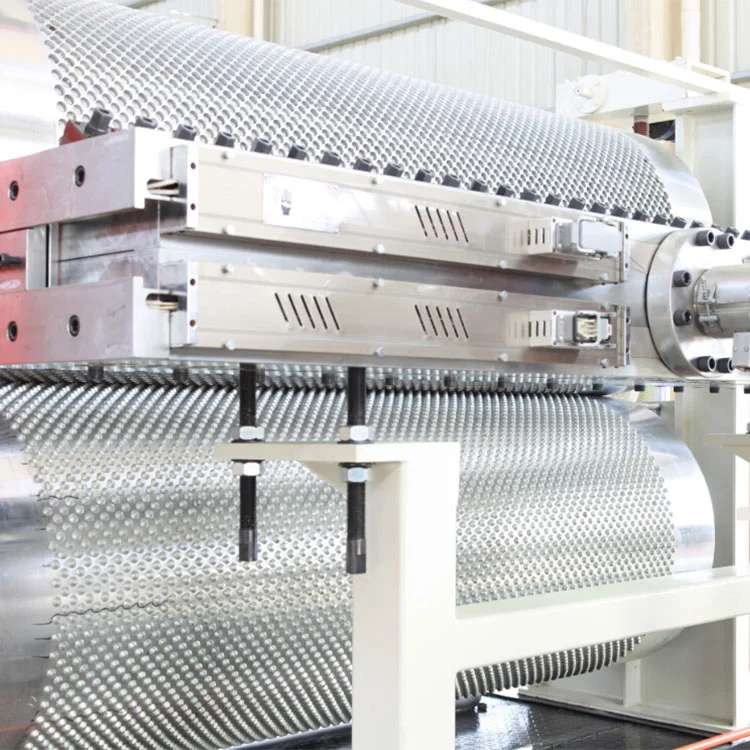

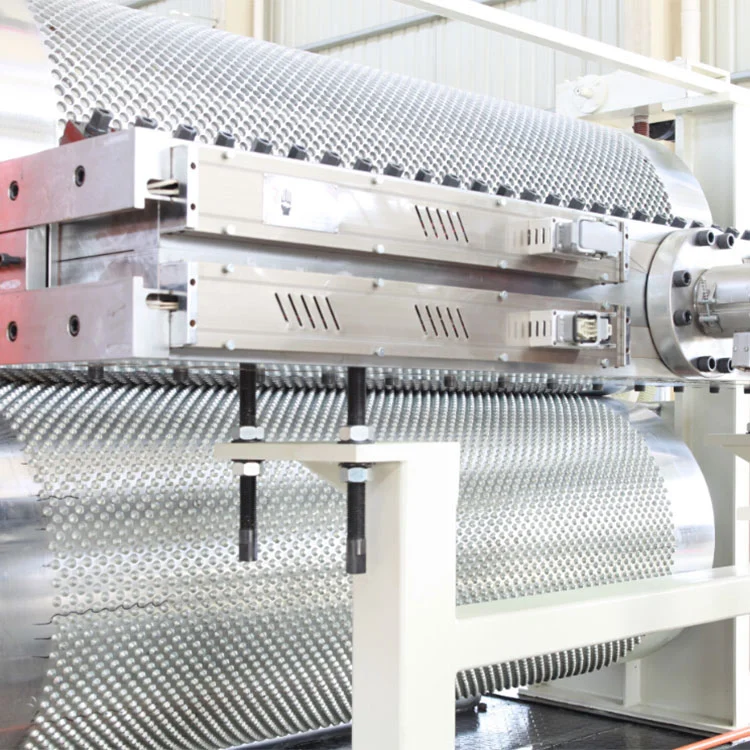

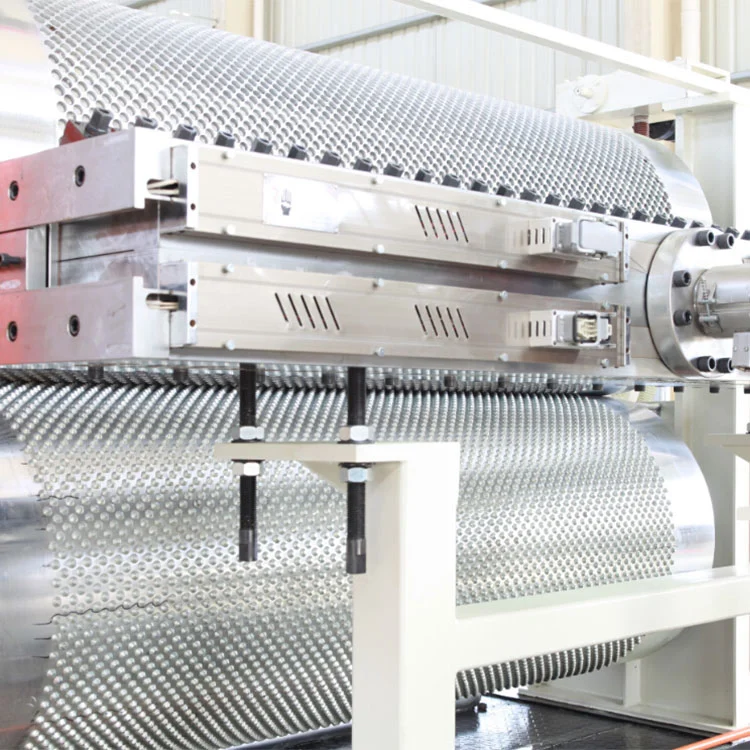

Welcome to the future of efficient drainage production with the HDPE Drainage Board Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This state-of-the-art equipment is designed for manufacturing high-density polyethylene (HDPE) drainage boards, which are essential in construction, landscaping, and environmental projects. These boards facilitate water drainage, prevent soil erosion, and enhance structural integrity in applications like green roofs, foundation walls, and sports fields. By investing in this machine, you're not just buying a product—you're unlocking a reliable, high-performance solution that streamlines your production line and delivers consistent quality.

At the heart of this machine lies advanced extrusion technology, ensuring precision and durability. Crafted with premium materials, it offers robust performance under demanding conditions, reducing downtime and maintenance costs. The intelligent design incorporates energy-efficient components, cutting operational expenses while maximizing output. With a focus on user-friendly operation, it features intuitive controls and automated systems that minimize manual intervention, making it ideal for both seasoned operators and newcomers. Backed by Qingdao Eaststar Plastic Machinery Co., Ltd.'s commitment to excellence, this machine comes with comprehensive quality assurances, including warranty support and technical guidance, so you can produce with confidence.

Imagine facing common industry challenges like inconsistent board thickness, high energy consumption, or frequent breakdowns. Our HDPE Drainage Board Extruder Machine addresses these head-on with innovative solutions. For instance, its precision calibration system ensures uniform board dimensions, while the optimized screw design enhances material flow and reduces waste. Below is a summary of key parameters that highlight its capabilities:

| Parameter | Value | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/h | High production efficiency for large-scale projects |

| Power Consumption | Optimized to reduce by 15% compared to standard models | Lower operational costs and environmental impact |

| Board Thickness Range | 10-50 mm | Versatility for various application needs |

| Machine Weight | Approx. 5,000 kg | Sturdy construction for long-term use |

| Control System | Fully automated with PLC interface | Easy operation and minimal training required |

This machine is tailored for a wide range of users, including construction companies, civil engineers, landscape architects, and environmental consultants. It excels in scenarios such as urban drainage systems, agricultural land management, and infrastructure development. Whether you're working on a residential complex or a large industrial site, the HDPE Drainage Board Extruder Machine adapts to your needs, providing reliable performance in diverse environments. Its scalability makes it perfect for small workshops aiming to expand or large factories seeking to upgrade their equipment.

Using this machine evokes a sense of empowerment and relief. Picture the satisfaction of delivering projects on time, with boards that meet strict quality standards. It solves persistent issues like waterlogging and structural damage, transforming challenges into opportunities for growth. Clients report increased productivity, reduced material waste, and a stronger competitive edge. By integrating this machine into your workflow, you'll experience smoother operations, fewer delays, and the peace of mind that comes from dependable machinery.

What sets this HDPE Drainage Board Extruder Machine apart from competitors? It boasts unique features like a modular design for easy customization, advanced cooling systems that enhance product consistency, and compatibility with various HDPE grades. Unlike standard models, it incorporates noise-reduction technology for a quieter work environment and real-time monitoring sensors that alert operators to potential issues before they escalate. Qingdao Eaststar Plastic Machinery Co., Ltd. prioritizes innovation, ensuring that each machine undergoes rigorous testing to deliver superior performance and longevity.

What is the typical lifespan of this extruder machine?

With proper maintenance, the HDPE Drainage Board Extruder Machine can last over 10 years. Regular cleaning, lubrication, and adherence to operational guidelines will ensure optimal performance and minimize wear and tear.

Can it handle recycled HDPE materials?

Yes, this machine is designed to process both virgin and recycled HDPE materials efficiently. It includes features like enhanced filtration systems to handle impurities, making it an eco-friendly choice for sustainable production.

How much space is required for installation?

The machine typically requires a floor area of approximately 20 square meters, depending on the configuration. We recommend consulting with our technical team for a customized layout plan based on your facility.

Is training provided for operators?

Absolutely. Qingdao Eaststar Plastic Machinery Co., Ltd. offers comprehensive training sessions, either on-site or online, covering operation, maintenance, and troubleshooting to ensure you get the most out of your investment.

What kind of after-sales support is available?

We provide 24/7 customer support, spare parts availability, and routine maintenance services. Our global network ensures prompt assistance, so you can focus on production without worries.

Embrace innovation and efficiency with the HDPE Drainage Board Extruder Machine. Its blend of cutting-edge technology, user-centric design, and proven reliability makes it an invaluable asset for any project. From reducing operational hurdles to enhancing product quality, this machine empowers you to achieve more. Explore the possibilities and join countless satisfied customers who trust Qingdao Eaststar Plastic Machinery Co., Ltd. for their production needs. Start transforming your drainage solutions today—experience the difference that precision engineering and dedicated support can make.