PA POM Sheet Extruder Machine,PE PP Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,PE PP Board Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,PS Sheet Extruder Machine,Biodegradable Sheet Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PVC Sheet Extruder Machine

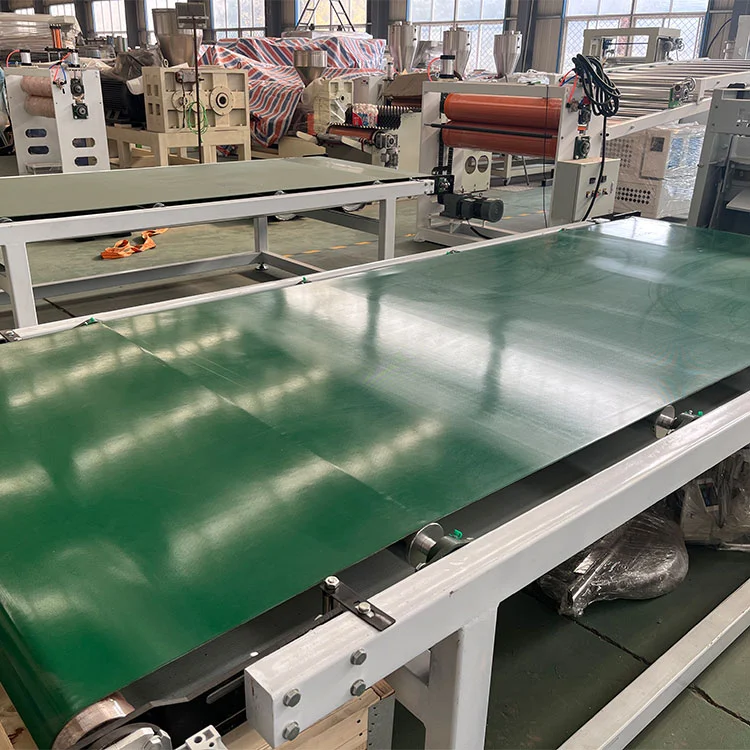

Welcome to the advanced world of plastic machinery innovation, proudly brought to you by Qingdao Eaststar Plastic Machinery Co., Ltd. Our PE PP Double-layer Co-extrusion Board Machine represents a leap forward in production efficiency, offering unmatched versatility and reliability for industries worldwide. Designed with precision engineering and cutting-edge technology, this machine empowers businesses to create high-quality double-layer boards that meet diverse application needs, from packaging to construction. By seamlessly blending PE and PP materials, it delivers boards with superior strength, durability, and aesthetic appeal, all while optimizing energy consumption and reducing waste. Join countless satisfied clients who have transformed their production lines with this state-of-the-art equipment, and discover how it can elevate your operations to new heights. Let's dive into the details that make this machine a must-have for modern manufacturers.

At its core, the PE PP Double-layer Co-extrusion Board Machine is engineered for versatility and high-performance output. It specializes in producing double-layer boards by co-extruding polyethylene (PE) and polypropylene (PP) materials, resulting in products that combine the best properties of both polymers. This process ensures excellent impact resistance, moisture barrier capabilities, and flexibility, making the boards ideal for applications such as industrial packaging, agricultural covers, automotive components, and consumer goods. With a user-friendly interface and automated controls, operators can easily adjust settings for thickness, width, and layer composition, catering to specific customer requirements. The machine's robust construction guarantees long-term stability, minimizing downtime and maintenance costs. Whether you're a small workshop or a large-scale factory, this equipment adapts to your production pace, delivering consistent quality that builds trust and drives business growth. Experience the seamless integration of innovation and practicality, where every board produced reflects Qingdao Eaststar's commitment to excellence.

One of the standout features of this machine is its advanced co-extrusion technology, which allows for precise layer control and material distribution. Unlike single-layer alternatives, the double-layer design enhances product performance by combining PE's toughness with PP's rigidity, creating boards that resist cracking, warping, and environmental stressors. The extrusion system incorporates high-efficiency screws and barrels, optimized for minimal energy usage and maximum output rates. Additionally, the machine includes real-time monitoring sensors that detect variations in temperature and pressure, ensuring uniform board quality throughout the production run. Safety features, such as emergency stop buttons and overload protection, provide peace of mind for operators, while the modular design facilitates easy upgrades and part replacements. Qingdao Eaststar Plastic Machinery Co., Ltd. backs each unit with comprehensive technical support and warranty services, emphasizing our dedication to customer satisfaction. By investing in this machine, you're not just buying equipment; you're securing a partnership focused on innovation and reliability.

Many manufacturers face challenges like inconsistent board thickness, high material waste, and frequent machine breakdowns. Our PE PP Double-layer Co-extrusion Board Machine addresses these issues head-on with its precision engineering and smart design. For instance, the integrated digital control panel allows operators to set exact parameters, reducing human error and material loss. The table below outlines key technical specifications that highlight the machine's capabilities:

| Parameter | Value | Benefit |

|---|---|---|

| Max Output Width | Up to 2500 mm | Accommodates large-scale production needs |

| Layer Thickness Range | 0.5-10 mm per layer | Offers flexibility for various applications |

| Power Consumption | Optimized to reduce by 15% vs. standard models | Lowers operational costs and environmental impact |

| Production Speed | Adjustable up to 8 m/min | Enhances efficiency without compromising quality |

| Noise Level | < 75 dB | Creates a safer, more comfortable work environment |

These parameters ensure that the machine not only meets but exceeds industry standards, providing a reliable solution for businesses aiming to scale up their operations while maintaining cost-effectiveness.

This machine is tailored for a wide range of users, including packaging companies, agricultural suppliers, construction firms, and automotive part manufacturers. In packaging, it produces sturdy boards for boxes and pallets that protect goods during transit. In agriculture, the boards serve as durable covers for greenhouses or soil protection sheets, withstanding harsh weather conditions. Construction professionals use them for insulation panels or decorative elements, thanks to their weather-resistant properties. Automotive industries benefit from lightweight yet strong components that enhance vehicle efficiency. Each scenario demands reliability, and the PE PP Double-layer Co-extrusion Board Machine delivers just that, enabling users to meet tight deadlines and custom orders with confidence. By integrating this equipment into your workflow, you'll experience a sense of accomplishment as production bottlenecks disappear and product quality soars. Imagine the pride in delivering items that exceed client expectations, fostering long-term relationships and repeat business. This machine isn't just a tool; it's a catalyst for growth, transforming operational challenges into opportunities for innovation and success.

Compared to other co-extrusion machines on the market, the Qingdao Eaststar model stands out with its unique combination of affordability, durability, and technological sophistication. While many competitors focus on single aspects like speed or cost, our machine balances all elements, offering a lower total cost of ownership through reduced maintenance and energy savings. The co-extrusion process allows for custom layer ratios, giving users unparalleled flexibility in product design. Moreover, the machine's compatibility with recycled materials supports sustainability initiatives, appealing to eco-conscious businesses. Testimonials from users highlight how it has streamlined their production lines, with one client noting a 20% increase in output efficiency within the first month. This differentiation stems from Qingdao Eaststar's decades of expertise in plastic machinery, ensuring that every component is tested for performance and longevity. By choosing this machine, you're opting for a solution that evolves with industry trends, keeping you ahead of the competition.

Frequently Asked Questions:

What materials can this machine process?

It efficiently handles polyethylene (PE) and polypropylene (PP) resins, including virgin and recycled variants, allowing for versatile board production with consistent quality.

How does the co-extrusion technology improve board performance?

By combining two layers, it enhances properties like strength, moisture resistance, and flexibility, resulting in boards that outperform single-layer alternatives in durability and application range.

Is the machine difficult to operate for beginners?

No, it features an intuitive control system with automated settings and detailed manuals, making it accessible for new users while offering advanced options for experienced operators.

What kind of maintenance does it require?

Routine checks on screws, barrels, and sensors are recommended, with easy-to-follow schedules provided by Qingdao Eaststar to ensure long-term reliability and minimal downtime.

Can it be customized for specific production needs?

Yes, we offer customization options for output size, layer thickness, and additional features, tailored to meet unique business requirements and maximize efficiency.

What support services are available after purchase?

Qingdao Eaststar provides comprehensive support, including installation guidance, training, spare parts supply, and technical assistance, ensuring smooth operation throughout the machine's lifecycle.

Envision the transformative impact of integrating the PE PP Double-layer Co-extrusion Board Machine into your daily operations. Users often report a significant reduction in material waste, leading to cost savings and a smaller environmental footprint. The machine's reliability means fewer interruptions, allowing teams to focus on creativity and expansion rather than troubleshooting. Emotionally, this translates to reduced stress and increased job satisfaction, as consistent high-quality output builds brand reputation and customer loyalty. For business owners, it opens doors to new markets and revenue streams, fueled by the ability to produce specialized boards that meet evolving demands. By solving common production pains, this machine fosters a sense of empowerment and progress, turning challenges into achievements. It's more than an investment in equipment; it's a step toward a brighter, more efficient future for your enterprise.